Calcium Silicate Board / Fiber Cement Board Production Line

Nkọwa dị mkpirikpi:

Na Fiber Cement Board Ngwaahịa ejiri mee ihe n'ọtụtụ ụlọ na ụlọ ọrụ ịchọ mma,

Nkọwa ngwaahịa

Mkpado ngwaahịa

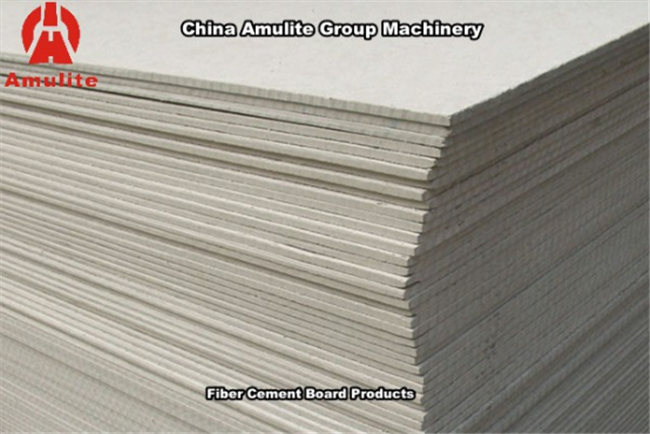

With Fiber Cement Board Products Wide Usage In Building And Decoration Industry,Fiber Cement Board Production Line Technology And Automatic Level Always Keep Upgrading All The Time.With Continuous Effort Of Amulite Engineers Team We Always Keep Technology Innovation and Make Our Fiber Cement Board Machinery Be ln Higher Level na World Cement Board Products Market ;Ugbu a, anyị na-enwe mgbe nile nrụpụta na inye Fiber Cement Board / Calcium Silicate Board Production Line With Capacity 3Million Sq.m Kwa afọ.4Million Sq.m kwa afọ.6Million Sq.m kwa afọ,8Million Sq.m kwa afọ,10Million Sq.m kwa afọ mgbe niile;Standard Board Size 2440X1220X(4-25)MM na 3000X1220X(4-25)MM, Ọzọkwa Anyị nwere ike hazie nrụpụta dị ka ndị ahịa ngwa ngwa. ' Ihe achọrọ, enwere ike imezu nkọwapụta ahaziri iche;

Ụdị na atụmatụ

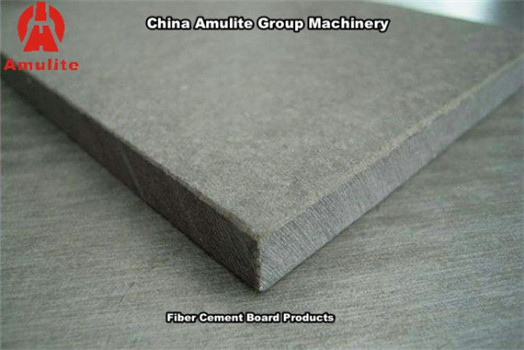

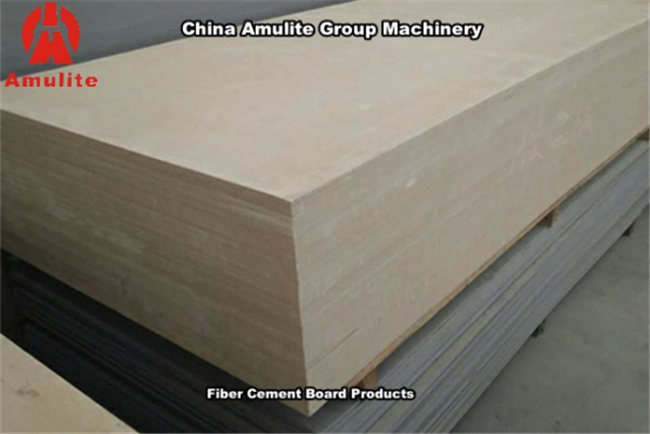

Fiber Reinforced Calcium Silicate Board/Fiber Cement Board Na-akpọkwa dị ka CSB/FCB Board.Dịka Ụdị Ọhụrụ na Ihe Ndị Na-echebe Gburugburu Ebe Obibi, Nke Nwere Uru nke Light Weight.High Strength, Fireproof, Good Heat Insulation Performance.Wide Usage and Long Lifetime Etc . Ugbu a, Calcium Silicate Board/Fiber Cement Board A na-eji ngwaahịa ndị a na-emepụta n'elu ụlọ na nkebi.

Teknụzụ mmepụta

Calcium Silicate Board/Fiber Cement Board Were Inorganic Fibers or Cellulose Fiber as Fiber Reinforced Materials.Were Calcium and Silicate Materials as Main Cementing Materials.With Production Process Slurry Mixing,Board Forming.Board Stacker,Pre-Curing,Demold Template,Autolave Curing Mepụta si,N'ihi na ụfọdụ Higher Standard Board Requirement.Can Tinye Board Press, Board ihicha, Board Sanding na Edge trimming Usoro, na-eme ka eserese na ihu ka mma Board Standard na ojiji, mgbe ahụ nwere ike dịkwuo ihe banyere Board agbakwunyere uru na ụba Board Sales Market. ;Maka imepụta bọọdụ nke Calcium Silicate Board/Fiber Cement Board Production Line na-ewerekarị Flow-on Slurry Forming Type,Hatchek Forming Type and Extrusion Type.

Isi ihe akụrụngwa

Fiber gbasiri ike (Kraft Paper Pulp,Wollastonite,Glass Fiber.Mica etc), Ngwa Silicate (Quartz Sand, Fly Ash, Diatomite etc}, Calcium Materials (Lime Powder, Cement), Ihe mgbakwunye wdg.

Standardkpụrụ ngwaahịa.

Calcium Silicate Board Industry Standards JCIT564-2008Fiber Cement Board Industry Standard JCIT 412.1-2006

Ntinye usoro mmepụta

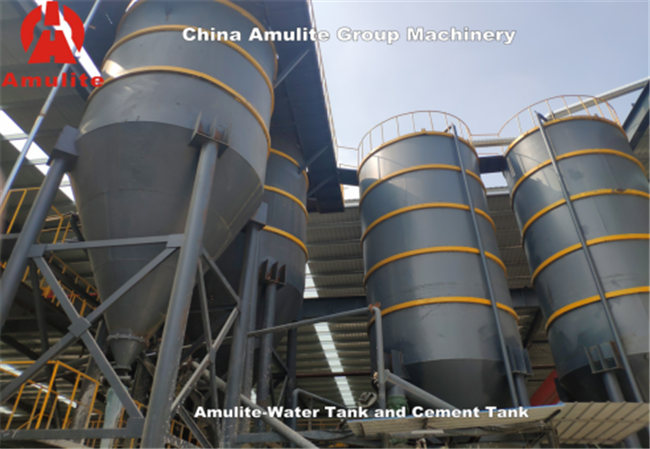

1. Water Tank na Simenti Tank Usoro

Enwere otu tank mmiri dị ọcha na otu tank mmiri na-asọ oyi; Abụọ mmiri tank ahụ na-agbaze site na carbon steel, a na-eji tank mmiri Muddy na-anakọta mmiri recycle mmiri site na usoro mmepụta nke mpempe akwụkwọ, mmiri apịtị were ka mix n'ime usoro slurry, maka ịdị ọcha. A na-eji tankị mmiri were were mmiri dị ọcha iji hichaa mmetụta na oghere net.

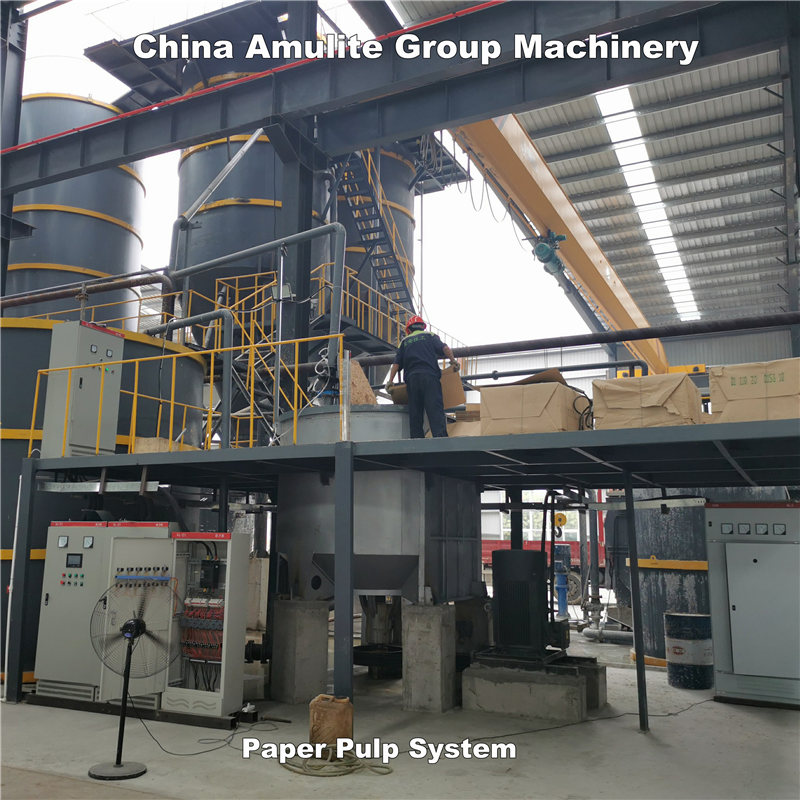

2.Paper Pulp Usoro

Usoro Pulp mpempe akwụkwọ na-agụnye igwe shredder mpempe akwụkwọ, onye nchacha, yana tank nchekwa akwụkwọ.

A na-eji Shredder mpempe akwụkwọ na-ekpochapụ akwụkwọ Kraft ahụ

A na-eji igwe nchacha a na-egweri akwụkwọ mpempe akwụkwọ ka ọ dị nro ma na-ebuga ya na tank nchekwa akwụkwọ.

A na-eji tankị nchekwa akwụkwọ mpempe akwụkwọ na-echekwa akwụkwọ.

3. Na-aga na Slurry Vacuum Usoro akpịrị ịkpọ nkụ mmiri

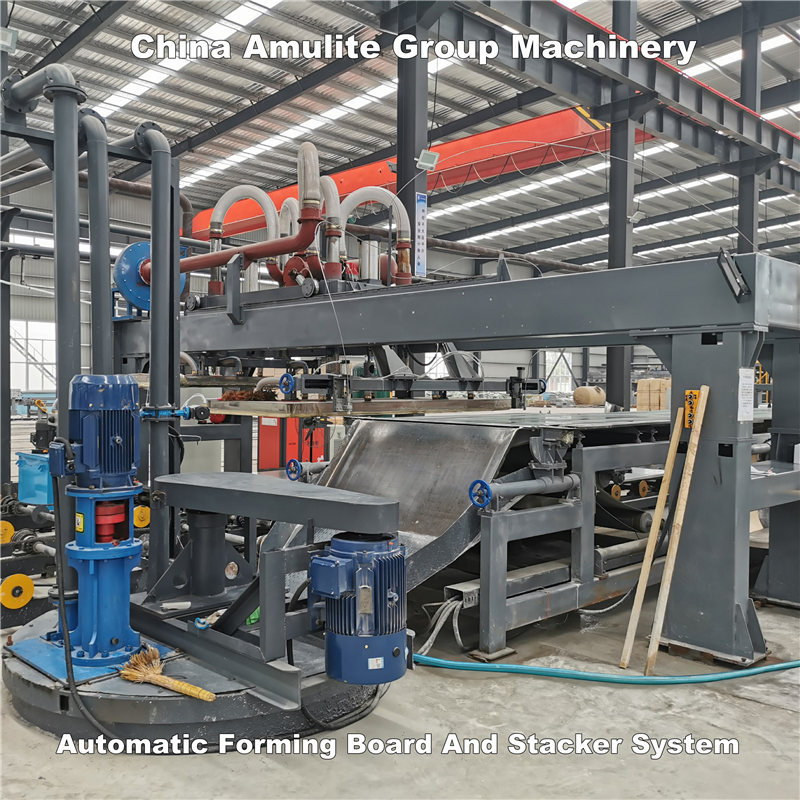

Nwere ike họrọ Flow-On Slurry akpụ Ibé akwụkwọ System ma ọ bụ Hatschek ụdị kpụrụ Ibé akwụkwọ Sistemu Form mpempe akwụkwọ, Anyị nwere ike hazie dị ka ahịa 'chọrọ.

Ngwakọta slurry agwakọta nke ọma na-asọba n'ime igbe slurry na-asọba, wee si na igbe slurry na-ebufe ka ọ na-agba ọsọ ka ọ bụrụ slurry Layer, na-enwe nkụda mmụọ na nkụchi obi iji mepụta mpempe akwụkwọ mpempe akwụkwọ, mgbe akwa akwa na-agbagharị okirikiri na-akpụ akwụkwọ mpempe akwụkwọ Drum Roller, wee jiri ịkpụ akpaaka Ụdị mpempe akwụkwọ mmiri dị larịị.

Nkewa ikuku-mmiri: A na-eji ya kewapụ ngwakọta mmiri Steam ewepụtara na igbe Vacuum, na-abanye n'ime ebe a na-anakọta, a na-ebugharị ikuku ahụ na mgbapụta Vacuum.

4.Flow-On Slurry mpempe akwụkwọ akpụ Usoro

Mgbe emechara akwụkwọ mpịakọta Roller, wee jiri ọnọdụ Laser akpaaka na ịkpụ, PC dum nke mpempe akwụkwọ mmiri na-abanye na usoro mbufe.

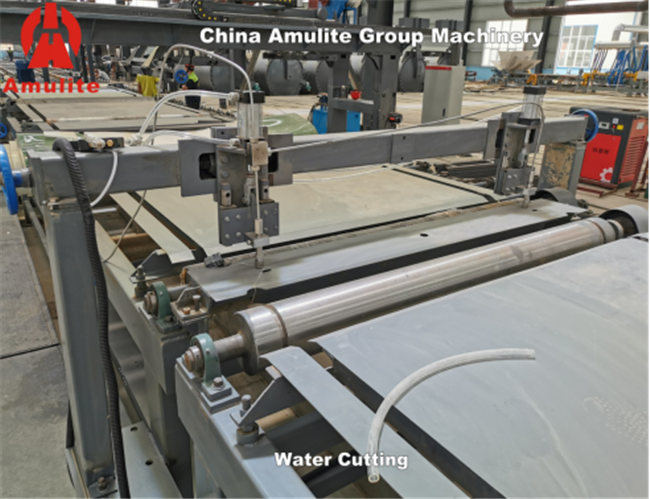

5.High Pressure Water Cutting System

Sistemụ ịkpụ mmiri a dị elu bụ ngwa patent nke anyị, na-eji mgbapụta mmiri na-ebubata dị elu iji mee ka mmiri dị elu mee ka ịcha akwa mmiri dị mma na mbufe.

6.Forming Wet Sheet na Wet Mpempe akwụkwọ na-ebufe Usoro

A na-eji usoro a na-ebufe mpempe akwụkwọ dị mma nke ọma site na imepụta Roller Nyefee mpempe akwụkwọ mmiri ahụ ka ọ nọrọ n'ọnọdụ ma mee ka ịkpụcha ihu akpaaka.

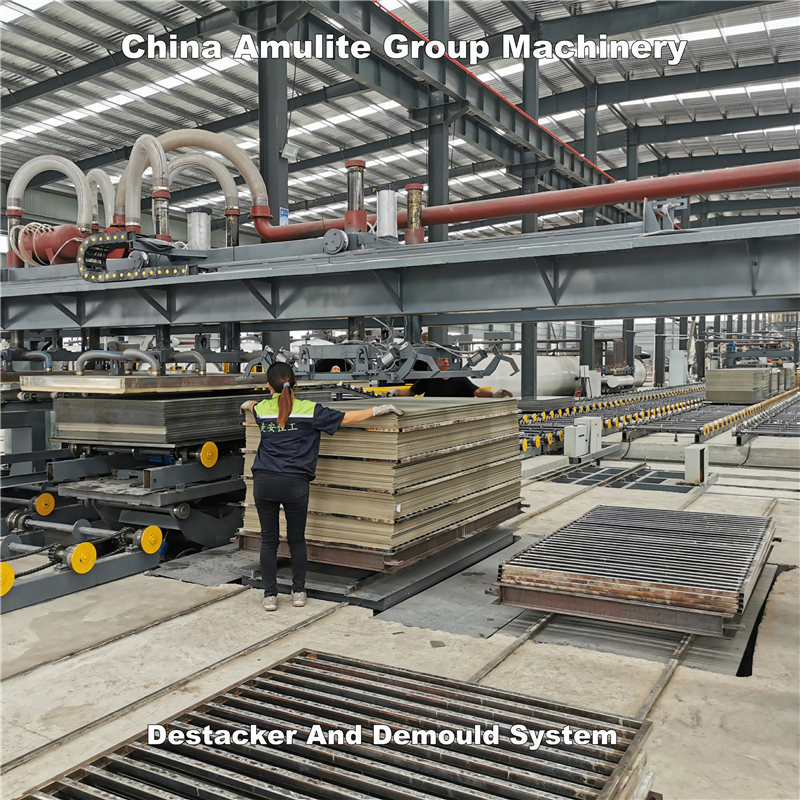

7. Akpaaka Stacker

Enwere ike ikpokọta mpempe akwụkwọ abụọ n'otu oge.Iko mmiri ahụ na-ekpochapụ akwụkwọ mmiri mmiri site na ịnata igwe na-ebufe ya na Template dị na Trolley n'ebe ọzọ na-arụ ọrụ, wee kpokọta ha na Trolley na Middle Position (Ya na Vacuum Suction Of High-Pressure Fan).Emeputara mmegharị ahụ ziri ezi nke iko mmiri mmiri site na Gear na ogwe aka Swing kpaliri site na mkpado hydraulic Push.

Njikwa PLC, Ọrụ akpaaka.

Arụ ọrụ: A na-eji Stacker akpaaka iji hazie ma chịkọta ngwaahịa dị mma na nke dị ala nke bọọdụ cement fiber / Calcium Silicate Board.

A na-akwakọba ngwaahịa ndị ahụ n'usoro ma na-arụ ọrụ nke ukwuu, nke ga-eme ka nrụpụta nrụpụta nke ọma.

8 .Pụrụ igwe

A na-eji igwe pịa iji bulie njupụta na ike nke ngwaahịa,

Ọkọlọtọ Nrụgide: 7000ton, Pịa Tebụl Size: 1350 * 2700/3200mm, Spacing: 1200mm, Na-arụ ọrụ strok: 400mm, mgbali ọsọ: 0.05 ~ 0.25mm / s;

Ọsọ nlọghachi: 15 mm / S

Ụgbọ njem ụgbọ njem na n'èzí: Otu nkeji.

Ike: 27.5kw

9.Trolley traction System

Ibu ekwenyere: 20T

Ogologo ụgbọ okporo ígwè okpokoro: 750mm

Usoro ije:

Ụdị mbelata: fa67-60-y-1.5, I = 50

Ọsọ moto dabara adaba: 1380r / min, Ike: 1.5kw

Ọsọ njem nke Trolley: 9m / min

10. Vacuum Demoulding Template Machine

A na-achịkwa mmegharị nke ụgbọ ala na ịrị elu na ọdịda nke iko mmiri ara ehi site na Servo Motor.

Igwe ihe nbibi na-ekewapụta Template na mpempe akwụkwọ dị na Trolley, Template a na-etinye na igwe ahịhịa mmanụ ka ọ na-ahịhịa mmanụ, a na-akwakọbakwa akwụkwọ ndị ahụ n'akụkụ Trolley nke ọzọ.Tinye otu Autoclave Interleave Spacer maka mpempe akwụkwọ 150 mm ọ bụla.

Emepụtara mmegharị ahụ ziri ezi nke iko mmiri mmiri site na Gear na ogwe aka Swing kpaliri site na mkpanaka pneumatic Push.

Njikwa PLC, Ọrụ akpaaka.

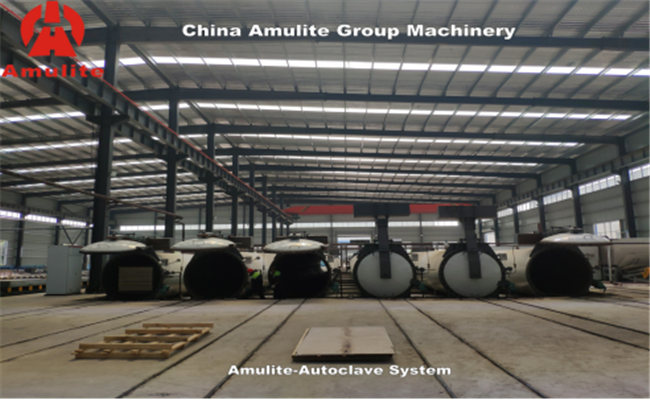

11.Autoclave Usoro

N'ihi njirimara nke Fiber Cement Board / Calcium Silicate Board, Lime na Quartz Sand Powder na-eji dị ka isi ihe ndị na-emepụta ihe na usoro mmepụta, nke chọrọ iji nweta mmeghachi omume kemịkalụ n'okpuru oke okpomọkụ na gburugburu ebe nrụgide dị elu, nwere ike ikwe ka ihe niile agwakọta. Zuru oke, ma mee ka mpempe akwụkwọ ahụ dịkwuo ike na ike.

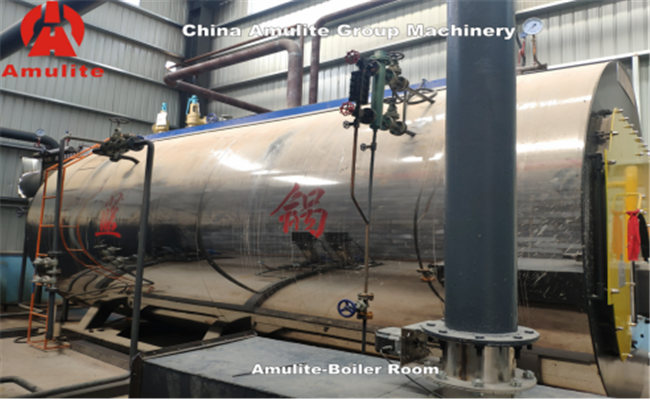

12. Igwe ọkụ

Na usoro mmepụta nke Fiber Cement Board / Calcium Silicate Board, Autoclave na Dryer na-eji maka nhazi, yana

A na-enye ike ọkụ nke Autoclave na Dryer site na mmiri ọkụ!

13. Drayer

A na-eji ya maka ihicha Fiber Cement Board / Calcium Silicate Board, Mgbe Autoclave Curing, Ọdịnaya Ọdịnaya nke Fiber Cement Board bụ ihe dịka 25%.Tupu Sanding, Edging na Chamfering, The Moisture

Ekwesịrị ibelata ọdịnaya ka ọ dị ala karịa 15% Site na nkụ.Dryer nwere uru nke nrụpụta dị elu, ọdịdị mara mma, mmezi dị mma yana ịrụ ọrụ dị mfe.

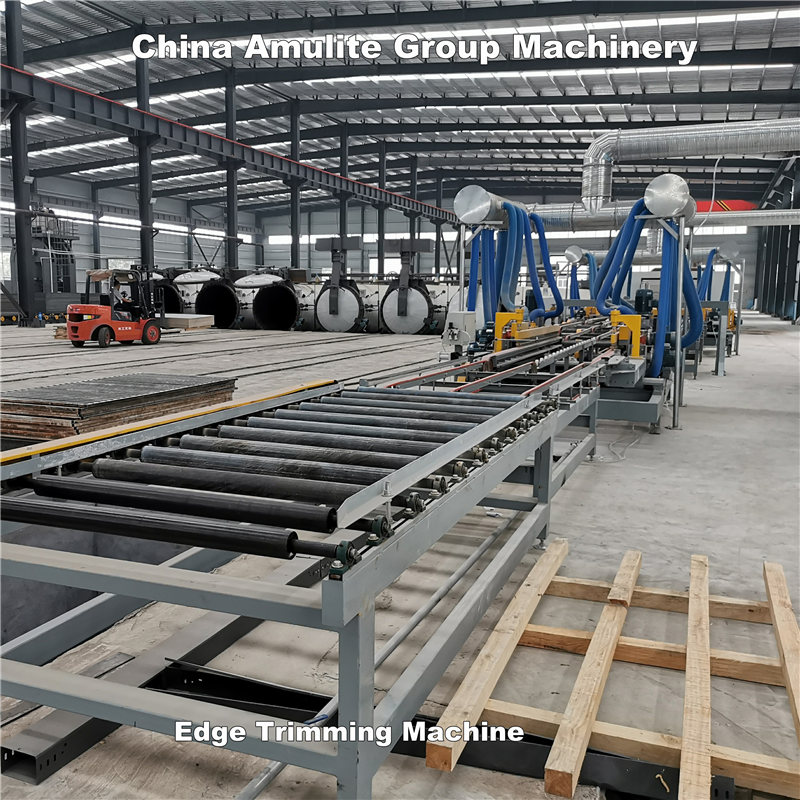

14. Edging Trimming System

The Edge Trimming Machine bụ tumadi mejupụtara nke mpempe akwụkwọ na-enye nri Roller table, Longitudinal Edge trimming Machine, Steering table, Transverse Edge Trimming Machine, Ibé akwụkwọ na-ebugharị Roller table, Electric Cabinet, Air Cabinet, etc;

A na-eji igwe na-akpụ akpụ Edging mee Edging na mbelata nke bọọdụ ciment nke eriri, wee na-akwakọba ngwaahịa ga-emecha.