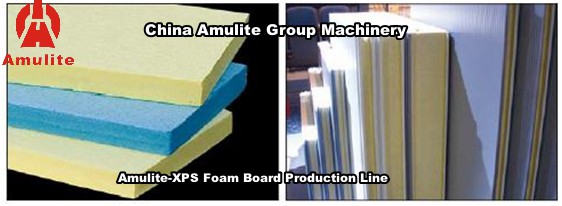

Amulite CO2 XPS Foam Board Production Line

Nkọwa dị mkpirikpi:

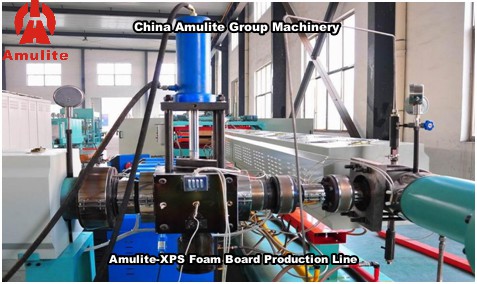

I.Nkà Okwu Mmalite

Mbụ, compounding symmetrical1y XPS ihe na ndị ọzọ inyeaka ihe dị ka ihe nucleicent na agba ogbe; Nke abụọ tinye ha n'ime hopper nke Grade Iextruder site agụụ feeder automatical1y; Nke atọ agbaze na plasticizing resin byspecial1y haziri ịghasa symmetrically, n'otu oge ahụ ịgbanye ụfụfụ gị n'ụlọnga site elu nrụgide na ịgwakọta. ya na gbazee resin; nke anọ, na-etinye ha n'ime Grade IIextrusion usoro izute, mix, tinye nrụgide na jụụ ọzọ na extruding ụfụfụ boardby pụrụ iche ebu maka osisi, mgbe ahụ jụrụ na akpụ osisi site jụrụ na akpụdexiss..kifthly.na-etinye osisi n'ime Grade I draw-off system and transporting theminto Grade Il draw-off system by Transport rol1s;Nke isii, na-egbutu ihe mkpofu ahihia nke akụkụ abụọ na imecha ịcha transverse dị ka ogologo 1ength siri dị;Nke mbụ nzọụkwụ, stacking na nchekwa.

Nkọwa ngwaahịa

Mkpado ngwaahịa

Ngalaba eletrik:

Isi moto Beide Brand (Siemens Standard Motors Ltd.)

Onye ntụgharị Danfoss ma ọ bụ Siemens Brand

AC Contactor Siemens ma ọ bụ Schneider Brand njikwa okpomọkụ mita Omron Brand ma ọ bụ Fuji Brand Voltage 380V,50HZ

AM-XPS75P/200 CO2XPS Foam Board Production Line

I.Teknụzụal Okwu mmalite

Nke mbụ, iji ihe enyemaka ndị ọzọ jikọta ihe XPS symmetrically dị ka ihe nrụnye na ogbe agba;Nke abuo tinye ha n'ime hopper nke Grade m extruder site agụụ feeder na-akpaghị aka;Nke atọ agbaze na plasticizing resin site pụrụ iche e mere ịghasa symmetrically, n'otu oge injecting ụfụfụ gị n'ụlọnga site elu nrụgide na ịgwakọta ya na gbazee resin;Nke anọ, na-etinye ha n'ime Grade II extrusion usoro na-agbaze, mix, tinye nrụgide na jụụ ọzọ na extruding ụfụfụ osisi site pụrụ iche ebu maka osisi, mgbe ahụ jụrụ na akpụ osisi site obi jụrụ na akpụ ngwaọrụ;Fifthly, na-etinye osisi n'ime Grade m ise- gbanyụọ sistemu na ibuga ha

n'ime usoro ndọpụta nke ọkwa nke Abụọ site na mpịakọta njem;Nke isii, na-egbutu ihe mkpofu site na

hụrụ nke abụọ-n'akụkụ na finishing transverse ịcha dị ka set ogologo;ikpeazụ nzọụkwụ, stacking na nchekwa.

II.Isi Ihe onwunwe

1> XPS resin

2> Onye na-ahụ maka ụfụfụ & na-enyere onye na-ahụ maka ụfụfụ aka 3> onye na-ahụ maka nuklia

4> Agba agba

5> Ihe enyemaka ndị ọzọ

Mara: Anyị ga-enye ndị ahịa anyị akwụkwọ ndenye ọgwụ, ụdị ihe na akwụkwọ teknụzụ ikwu mgbe ha bịanyere aka na nkwekọrịta.

Ngwakọta igwe

1> Plastic igwekota 1 set

2> Ọkwa m extrusion usoro 1 set

3> CO2Sistemụ ịgba ọgwụ ụfụfụ 1 set 4> Sistemụ ịgbanye ụfụfụ onye enyemaka 1 set 5> CO2Sistemụ ihe ngosi ihe ngosi 1 set 6> HCFC Foam agent injection system 1 set 7> Sistemụ mgbanwe ntanetị akpaaka 1 set

8> Ọkwa II extrusion usoro 1 set

9> Extrusion anwụ isi 1 set

10> Usoro nhazi na ịdọpụpụ 1 set

11> Nbufe na jụrụ usoro 1 set

12> Ọkwa II ndọpụta-apụ usoro 1 set

13> Ogologo oge ịkpụ usoro 1 set

14> Sistemụ igbutu kwụ ọtọ 1 set

AM-75P/200 CO2Line Production Board XPS Foamed

1.Nri usoro

2.AM75/44Ejima-ịghasa extruder 1 setịpụrụ

3.CO2sistemu ịgba ọgwụ ụfụfụ1 setịpụrụ

4.Onye enyemaka ụfụfụ ogwu ogwu usoro 1 set

5.Sistemụ ịgba ọgwụ nje Freon Foam 1 setịpụrụ

6.CO2eruba gosi usoro 1 set

7.Akpaaka net-exchange usoro 1 set

8.Ọkwa II extrusion usoro 1 setịpụrụ

9.Extrusion anwụ isi 1 set

10.Sistemụ nyocha na mwepu 1 setịpụrụ

11.Sistemụ nnyefe na jụrụ oyi 1 setịpụrụ

12.Ọkwa II ịdọrọ-apụ usoro 1 set

13.Ogologo ogologo ịcha usoro 1 set

14.Kehoraizin ịcha usoro 1 set

15> ntụgharị ịcha usoro 1 set

15.Igwe ọkụ eletrik

XPS Foamed Board Recycling and Pelletizer Machine

Nlereanya AM-XPS-JR100B

1> XPS bọọdụ ụfụfụ ihe nhịahụ ngwaọrụ 1 setịpụrụ

2> Single ịghasa plasticizing na extrusion ngwaọrụ 1 setịpụrụ

3> Nzacha net-agbanwe ngwaọrụ 1 setịpụrụ

4> Na-ajụ oyi tankị 1 set

5> Ịcha pellet igwe 1 set

Mara: Oke dị n'elu nke onye na-ahụ maka ụfụfụ bụ naanị maka ntụaka gị, a na-edozi data ahụ n'ezie dịka ihe achọrọ na ahịa si dị.